- Home

- »

- Glossary Of Terms

- »

- Labor Costs

What are Labor Costs?

A Practical Guide for Small Businesses, Contractors & Blue-Collar Pros

If you run a small business, are a contractor, or work in home services or field services like HVAC, plumbing, landscaping, or construction—you’ve probably heard the term “labor costs” thrown around. But what does it really mean? And more importantly, how do you track it, reduce it, and price jobs profitably?

Let’s break it all down.

Definition: What Are Labor Costs?

Labor costs are the total expenses you incur to employ workers—whether they’re hourly, salaried, full-time, part-time, or subcontractors.

They include:

- Wages or salaries

- Payroll taxes

- Employee benefits

- Overtime

- Training

- Workers’ comp insurance

- Paid time off (PTO)

- Tools, uniforms, and equipment used by employees

The Two Types of Labor Costs

1. Direct Labor Costs

These are wages and expenses directly tied to producing a service or product.

Example:

- A plumber installing a water heater

- A construction worker framing a house

- An HVAC tech fixing an AC unit

- A lawn care crew mowing and edging a property

2. Indirect Labor Costs

These are costs that support the job, but don’t directly perform it.

Example:

- A dispatcher scheduling the technician

- A manager overseeing multiple crews

- HR handling payroll and hiring

- Office assistant answering calls

🔑 Tip: Both types impact your bottom line. If you ignore indirect labor, you’re underestimating the real cost of doing business.

What’s Included in Labor Costs?

| Cost Type | Description | Example |

|---|---|---|

| Hourly wages | Pay based on time worked | $25/hour for a technician |

| Salaries | Fixed annual pay | $60,000/year for a project manager |

| Overtime pay | Time-and-a-half after 40 hours (per federal law) | $37.50/hour for overtime (on a $25/hour base) |

| Payroll taxes | Social Security, Medicare, unemployment, etc. | ~7.65% of gross pay (employer portion) |

| Workers’ comp | Insurance in case a worker is injured | Varies by state and industry risk |

| Health insurance | Employer-paid or shared health plan premiums | $300/month per employee |

| Retirement match | 401(k) or IRA contributions from employer | 3% employer match |

| Training & onboarding | Cost of preparing new hires | $1,000 per new HVAC tech |

| PTO (vacation, sick) | Paid time when not working | 2 weeks paid time off annually |

| Company vehicle/fuel | Costs for transporting employees to job sites | $0.67/mile or fleet leasing cost |

| Tools & gear | Tools, boots, uniforms, gloves | $500/year per worker |

| Software/tools | Field service software, time tracking apps, payroll platforms | $15–$50/month per user |

Labor Cost Example: Residential HVAC Job

Scenario: You send an HVAC tech to install a new furnace.

- Tech’s hourly wage: $28/hour

- Job takes: 6 hours

- Payroll tax: 7.65%

- Workers’ comp: $2/hour

- Benefits cost: $5/hour

💡 Total Labor Cost:

| Description | Amount |

|---|---|

| Base wage | $168 |

| Payroll tax (7.65%) | $12.85 |

| Workers’ comp | $12 |

| Benefits | $30 |

| Total | $222.85 |

If you only charge the customer $168 for labor, you’re losing $54+ in real cost.

Why Knowing Labor Costs Matters

- Job Pricing Accuracy: Underestimate labor, and you eat the cost. Overestimate it, and you lose bids.

- Profit Margin Control: You can’t grow if you don’t know what each job really costs.

- Hiring Smarter: Understand what each employee costs your business—not just what you pay them.

- Job Costing & Estimating: Break jobs into labor hours and rates to create precise estimates.

- Cash Flow Forecasting: Labor is often your biggest expense. Nail it, and your business stays healthy.

How to Reduce or Control Labor Costs

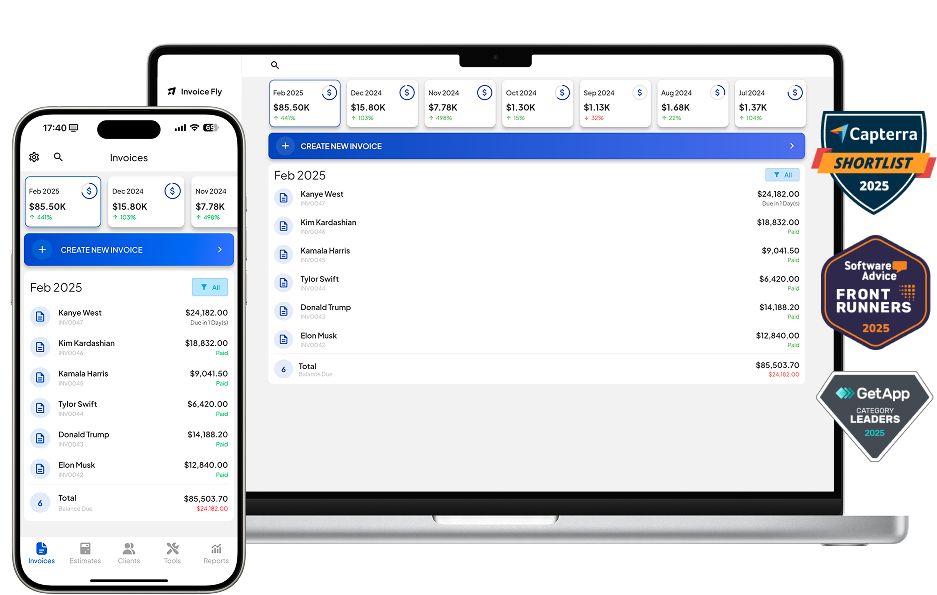

- Use time-tracking apps: Know how long jobs really take. Tools like Invoice Fly Time Tracker can help you reduce your business labor costs.

- Cross-train employees: More flexible crews = less downtime.

- Cut unproductive time: Track travel, setup, cleanup. Look for bottlenecks.

- Hire subcontractors when flexible labor is needed: Avoid long-term overhead.

- Use flat-rate pricing: Build average labor cost into fixed service prices.

- Outsource non-core work: Bookkeeping, HR, dispatching can often be handled for less.

- Invest in better tools & software: More efficient workers cost less per job.

How to Calculate Your Labor Burden Rate

The labor burden is the true cost of employing someone above their wage.

- Formula:

Labor Burden = (Total Annual Labor Cost ÷ Total Hours Worked) – Base Hourly Wage

Let’s say:

- Nick earns $25/hour

- Benefits, taxes, workers’ comp = $12,000/year

- Nick works 2,000 hours/year

Labor Burden = ($12,000 ÷ 2,000) = $6/hour

True Cost per Hour = $25 + $6 = $31/hour

Your break-even labor rate is $31/hour, not $25/hour.

Real-Life Industry Examples

| Industry | Labor Cost Example |

|---|---|

| Plumbing | 2 plumbers at $30/hr each + $8/hr burden = $76/hr real cost |

| Landscaping | Crew of 3 at $18/hr + $6/hr burden = $72/hr for team |

| Electrical | Licensed journeyman at $35/hr, 1 apprentice at $20/hr, total cost = ~$65/hr with burden |

| Cleaning | $17/hr cleaners + $5/hr burden = $22/hr real cost |

| Painting | One painter $25/hr + $6/hr burden = $31/hr; two-man crew = $62/hr |

Final Thoughts: Labor Cost = Profit Control

-

If you don’t know your labor costs, you’re guessing, not running a business.

Great businesses know their numbers. Labor is the #1 expense for most trades. Get it right, and you’ll price jobs better, pay employees fairly, and keep your business profitable.

FAQs about Labor Costs

The sequence for preparing a standard labour cost is to: Define the standard work, establish the work content and the quantity of labour (man-hours, man-days), and multiply the wage rate by the man hours to produce the standard labour cost.

Most businesses aim for a labor cost of around 25-35% of sales, shooting for under 30% whenever possible. For reference, your prime cost, which is the cost of labor plus the cost of goods sold (COGS), should land somewhere around the 60% mark.

According to Automotive Management Network, California has the highest average labor rates ($173).

An acceptable average cost percentage is 25-35% of gross sales. This varies depending on the business, industry, and location. For example, a retail store in a small town may have labor percentages less than 25%, while the manufacturing sector may have labor percentages higher than 35%.

The average labor cost percentage should typically be in the range of 20% to 35% of a company's gross sales. However, there are variations, depending on your field. It's not uncommon for restaurants and other service businesses to have a labor cost percentage of up to 50%.

Other Free Resources

Try Invoice Fly Today

- Send quotes & invoices in seconds

- Collect card & online payments

- Receive instant notifications

- Win more jobs