- Home

- »

- Glossary Of Terms

- »

- Material Costs

What are Material Costs?

A Straight-Talking Guide for Contractors, Tradespeople & Blue-Collar Businesses

Whether you’re running a handyman company, HVAC crew, landscaping team, or a construction outfit—materials are the lifeblood of your jobs. But if you don’t fully understand your material costs, you’re putting your profits at risk.

This guide gives you everything you need to know, in plain English.

Definition: What Are Material Costs?

Material costs are the total expenses your business incurs for the physical items or supplies used to complete a job or service.

They include:

- Raw materials: lumber, concrete, copper pipe, etc.

- Consumables: screws, nails, glue, etc.

- Pre-fab products: water heaters, light fixtures, fencing panels, etc.

- Packaging or shipping costs.

- Sales tax on materials.

- Waste, spoilage, or overage factors.

- Delivery charges or fuel surcharges.

- Storage, handling, and shrinkage.

The Two Types of Material Costs

1. Direct Material Costs

These are materials used directly on a job and often visible to the customer.

Examples:

- Drywall for a remodel

- Pipes and fittings for a plumbing job

- Mulch and plants for landscaping

- Light fixtures for an electrical job

- HVAC unit or mini-split system

2. Indirect Labor Costs

These are not directly installed, but are still necessary to complete the job.

Examples:

- Caulk, tape, glue

- Cleaning supplies

- Sandpaper, bits, blades

- Trash bags, rags

- PPE (masks, gloves)

🔍 Note: Both direct and indirect materials affect your profit, but only direct materials are usually billed to clients unless you bundle costs.

What’s Included in Material Costs?

| Material Cost Component | Description | Example |

|---|---|---|

| Purchase price | Cost of buying the product or supply | $750 for a new water heater |

| Sales tax | State/local tax on purchases | 7% on $750 = $52.50 |

| Shipping/freight | Delivery or fuel surcharges | $65 for pallet shipping |

| Storage/handling | Cost of warehousing or moving materials | $100/month for storage unit |

| Spoilage or waste | Unusable, damaged, or leftover material | 10% extra concrete for waste |

| Return losses | Items that can’t be returned or restocked | $200 of custom tile non-refundable |

| Tools and packaging | Containers, packaging, buckets, blades used with the materials | $20 in buckets and mixing paddles |

Material Cost Example: Bathroom Remodel

You’re remodeling a customer’s bathroom. Here’s your material list:

| Item | Qty | Unit Cost | Total |

|---|---|---|---|

| Tile | 120 sq ft | $3.00 | $360 |

| Thinset mortar | 3 bags | $18.00 | $54 |

| Grout | 2 bags | $15.00 | $30 |

| Backer board | 6 sheets | $20.00 | $120 |

| Shower valve & trim | 1 | $220.00 | $220 |

| Sales tax (7%) | — | — | $54.20 |

| Delivery fee | — | — | $75 |

| Total Material Cost | $913.20 |

🔧 Real-World Examples by Industry

| Trade | Typical Materials | Estimated Cost Example |

|---|---|---|

| HVAC | Units, flex duct, copper line sets, refrigerant, wall brackets | $2,000–$5,000 for unit install materials |

| Plumbing | Pipe (PEX, copper, PVC), fittings, valves, glue, water heaters | $300–$2,000 per job |

| Electrical | Breakers, wire, outlets, fixtures, panels, conduit | $150–$1,500 depending on complexity |

| Landscaping | Plants, mulch, pavers, edging, gravel, sod | $100–$10,000 depending on job scope |

| Painting | Paint, primer, tape, drop cloths, brushes, rollers | $150–$600 per job |

| Roofing | Shingles, underlayment, nails, flashing, sealants | $1.20–$4/sq ft material only |

How to Estimate Material Costs Accurately

Go room-by-room or area-by-area. Measure exactly how much you’ll need before quoting.

Add Overage % for Waste

Common guidelines:

- Flooring/Tile: 10–15%

- Paint: 10%

- Mulch/Gravel: 5–10%

- Lumber: 10–20% (warping, trimming)

Include All “Hidden” Material Costs

Don’t forget:

- Delivery fees

- Restocking fees

- Return shipping

- Consumables and tools used per job

How to Reduce Material Costs

- Buy in bulk: Leverage volume discounts from suppliers.

- Use trade accounts: Home Depot Pro, Lowe’s Pro, Ferguson, etc. often offer better pricing.

- Track material usage: Prevent over-ordering and theft. Use barcode or job tracking systems.

- Avoid spoilage: Store properly to avoid weather or moisture damage.

- Standardize materials: Use the same brand/skus across jobs for easier purchasing and inventory.

- Return unused items promptly: Many vendors have strict restocking windows.

- Negotiate with suppliers: Especially for recurring or high-volume projects.

Material Costs vs. COGS vs. Markup

| Term | Meaning |

|---|---|

| Material Costs | What you pay to get the materials into your shop/truck |

| COGS | “Cost of Goods Sold” – includes both labor & material per job |

| Markup | What you add to the cost to cover overhead + profit |

Example: How Markup Impacts Profit

- Material cost: $800

- Labor cost: $700

- Total cost: $1,500

- Markup: 50%

- Final customer price: $2,250

- Gross profit: $750

💡 You can’t just pass along material costs 1:1. You need to mark them up to cover handling, time, and risk.

Final Takeaway: Know Your Material Costs = Protect Your Profit

You can’t manage what you don’t measure.

For every job, ask:

- Did I track every single item used?

- Did I price my materials high enough to make a profit?

- Am I buying smart and managing waste?

Understanding your real material costs means:

- Better estimates

- Fewer surprises

- Higher margins

- A more professional business

FAQs about Material Costs

What Is Cost of Goods Sold (COGS)? Cost of goods sold (COGS) refers to the direct costs of producing the goods sold by a company. This amount includes the cost of the materials and labor directly used to create the good. It excludes indirect expenses, such as distribution costs and sales force costs.

Actual costing is a specific cost accounting method that precisely records real costs incurred during production, including direct material, direct labor, and manufacturing overhead costs.

In summary, the key differences between a supply and a material are: Supplies are treated as expenses, while materials are treated as assets. You can deduct the cost of your supplies in the year that you purchase them. Materials used to produce your products are on the other hand treated as an “asset until sold”.

The total square footage of material for the project is multiplied by the material cost for each category or element. In the case of equipment, appliances, doors, windows, and furnishings, the cost for one each is multiplied by the total required for the entire project.

This includes general office supplies, such as pens, paperclips, printers, envelopes, postage stamps, and the like. You generally can only deduct the cost of supplies and materials if you use them in your business during the tax year (unless you deducted them in a prior year).

Other Free Resources

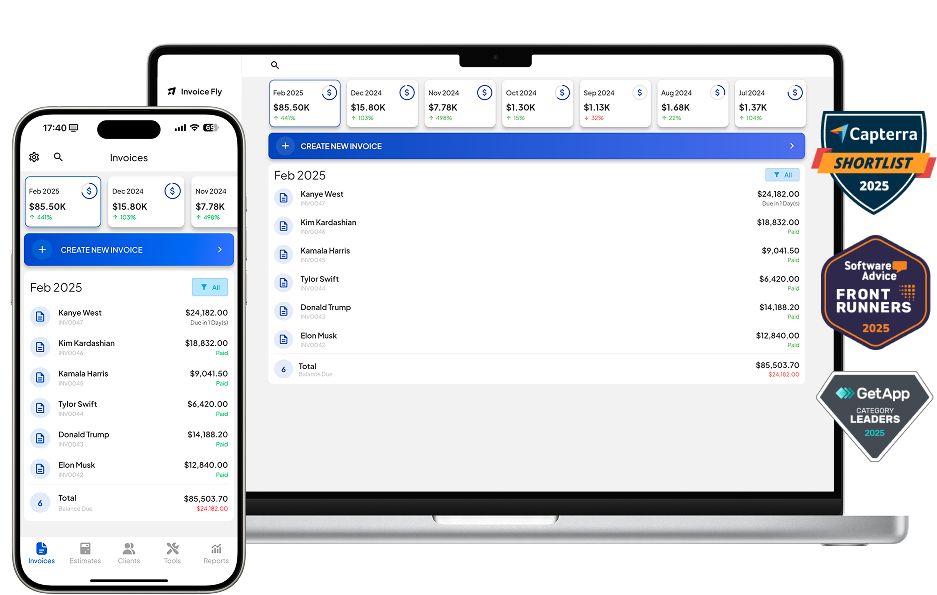

Try Invoice Fly Today

- Send quotes & invoices in seconds

- Collect card & online payments

- Receive instant notifications

- Win more jobs