- Home

- »

- Glossary Of Terms

- »

- FIFO, First In, First Out

FIFO - First In - First Out

FIFO—short for First In, First Out—is a method and control system that ensures the oldest items (first received or produced) are the first used, sold, or processed. It’s widely applied in inventory accounting, warehouse storage, restaurants and kitchens (food rotation), manufacturing flow, retail replenishment, and even operating-system scheduling. In accounting, FIFO is a cost-flow assumption: it assigns the cost of the earliest inventory layers to COGS first.

How FIFO works in inventory & accounting

Under FIFO, when you sell or use inventory, you expense the oldest cost layers first and keep the newest costs in ending inventory. This doesn’t force a physical pick path—it’s an assumption used to value COGS and inventory on financial statements.

Quick numeric example

- Buy 100 units @ $10 → then 100 units @ $12

- Sell 150 units → under FIFO, COGS = 100×$10 + 50×$12 = $1,600

- Ending inventory = remaining 50 units @ $12 = $600

Price effects: In periods of rising prices, FIFO usually yields lower COGS and higher ending inventory than LIFO; in falling prices, the effect reverses. FIFO is permitted under both U.S. GAAP and IFRS (while LIFO is not allowed under IFRS).

FIFO in kitchens & food safety (restaurants)

FIFO is standard for food storage and rotation to protect quality and safety. Staff label deliveries with dates, place newer stock behind older stock, and use the oldest first. This reduces spoilage, improves consistency, and supports health-code compliance.

- Storage: Oldest dated items at the front or top; newest go to the back or bottom.

- Prep line: Batches prepared earlier get plated first.

- Benefits: Less waste, reliable use-by control, higher perceived quality.

FIFO in warehouses, retail & manufacturing

In warehousing and retail, FIFO aligns bin layouts, pick paths, and WMS rules so older receipts exit first—critical for products with expiry dates, serial/lot tracking, and consistent quality. In manufacturing, FIFO lanes help maintain sequence, reduce work-in-process (WIP), and expose flow problems sooner.

- Retail: Shelf replenishment keeps older stock forward to avoid markdowns due to aging.

- Manufacturing: FIFO lanes and kanban reduce stagnation and rework risk.

- Quality: Age-sensitive materials (adhesives, chemicals) benefit from strict rotation.

FIFO in computing & scheduling

Operating systems and queues often use a FIFO discipline: the job or request that arrives first is served first. It’s simple and fair but can lead to long waits for later tasks if the first job is large.

FIFO vs. LIFO (and Weighted Average)

- FIFO: Oldest costs → COGS first; newest costs → ending inventory. Often higher reported profit during inflation.

- LIFO: Newest costs → COGS first; oldest costs → ending inventory. Allowed under U.S. GAAP, not under IFRS.

- Weighted Average: Spreads total cost evenly across all units; smooths price swings.

Which is best? Depends on your cost volatility, margins, and reporting goals. Many global companies adopt FIFO for IFRS compatibility and operational simplicity.

Benefits and limitations

Benefits

- Intuitive; mirrors natural physical flow for perishables and dated goods.

- Often higher inventory valuation and cleaner balance sheet in inflationary periods.

- Supports quality and compliance in food, pharma, and cosmetics.

Limitations

- May overstate profit in rising-cost environments (lower COGS → higher taxable income).

- Physical operations must enforce rotation to realize the quality benefits.

- Not always optimal for volatile commodity inputs or when tax minimization is the priority (where LIFO could help under U.S. GAAP).

Impact on invoicing & reporting

FIFO doesn’t change the invoice price you charge customers, but it changes your COGS and gross margin. If you sell items purchased at different costs, FIFO determines which costs hit today’s P&L. For accurate profit analytics alongside your invoices, pair your invoicing tool with an inventory module that tracks FIFO layers and feeds your accounting system.

Implementation checklist

- Label receipts with arrival/manufacture dates or lots.

- Design storage so newer stock sits behind older stock.

- Use WMS/ERP rules that enforce FIFO picks; audit exceptions.

- For kitchens: date-label, rotate daily, and train staff on “oldest first”.

- In accounting: select FIFO in your ERP; confirm financial statement and tax impacts.

Related terms: LIFO, Weighted Average Cost, Perpetual vs. Periodic Inventory, COGS, WMS, Kanban, Expiry/Lot Control.

FAQs FIFO

A FIFO job (Fly-In, Fly-Out) is a work arrangement commonly used in industries like mining, oil, and large-scale construction. Employees are flown to remote worksites for a scheduled period (e.g., 2 weeks on, 1 week off) and then flown back home. It allows workers to earn high wages while living in urban centers, but it often involves long shifts and extended time away from family.

FIFO stands for First In, First Out. In logistics, inventory management, and accounting, it means the oldest stock or assets are used or sold first. In the context of jobs, FIFO also refers to “Fly-In, Fly-Out” employment.

The FIFO lifestyle refers to the unique way of living for workers on rotation schedules. It includes long periods away from home, followed by extended breaks. While it offers high salaries and blocks of free time, it can be mentally and physically challenging due to isolation, irregular sleep, and distance from loved ones.

In food storage, FIFO ensures older food items are used first to maintain freshness and reduce waste. For example, in restaurants and supermarkets, staff place newer stock behind older items to avoid expired goods.

Yes. FIFO jobs are not exclusive to Australia or Canada; Americans can find similar roles in remote oil fields, offshore rigs, and construction projects. However, most FIFO jobs are concentrated in countries with large mining industries.

FIFO jobs are well paid because they often require workers to stay in remote or harsh environments, work long shifts (sometimes 12+ hours), and endure isolation from family. Companies compensate with higher wages, travel allowances, and benefits.

An everyday example of FIFO is how milk is stocked in a supermarket. Older cartons are placed in front, and new ones behind. Customers typically take the first ones, ensuring older stock is used before it expires.

In warehouses, FIFO ensures older inventory is picked and shipped before newer arrivals. This system prevents stock from becoming obsolete, especially in industries dealing with perishables, electronics, or seasonal goods.

Other Free Resources

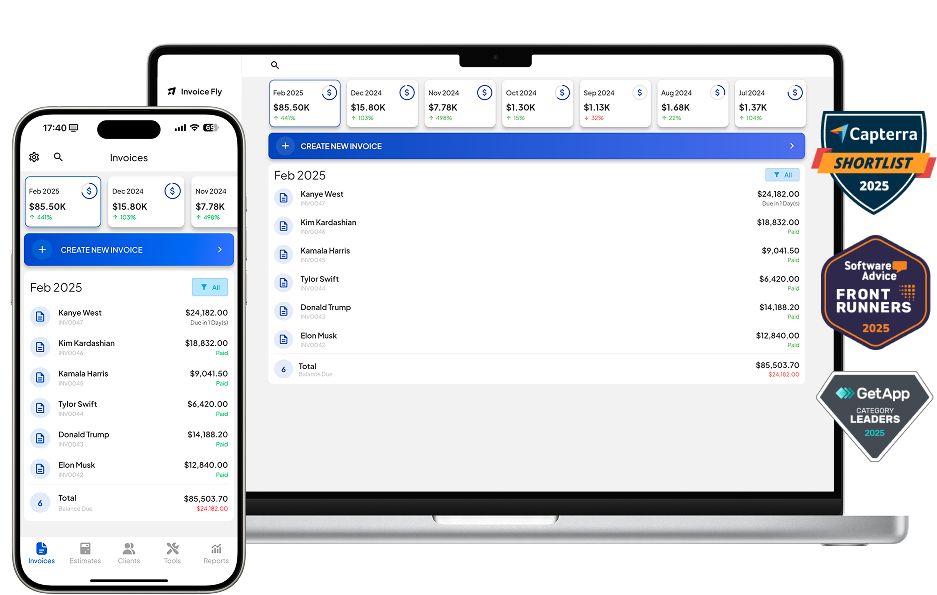

Try Invoice Fly Today

- Send quotes & invoices in seconds

- Collect card & online payments

- Receive instant notifications

- Win more jobs