What is Masonry & Types of Masonry in Construction?

Table of Contents

Masonry is one of the oldest and most reliable construction techniques in the world — used to build everything from ancient temples to modern office buildings. At its core, it means constructing structures from individual units such as brick, stone, or concrete blocks, bonded together with mortar.

This traditional method continues to play a major role in today’s construction industry, prized for its strength, durability, and timeless look. Whether you’re a contractor, builder, or small construction business owner, understanding how masonry works (and which type best fits your project) can make a major difference in quality, cost, and long-term performance.

This guide will cover:

- What it means in construction

- Common types like brick, stone, and concrete

- Materials and tools used in masonry work

- Key techniques, advantages, and challenges

- Modern applications and FAQs

Learn more about starting or expanding your construction business in our How to Start a Construction Company guide.

What Is Masonry?

In construction, masonry refers to the art and process of building structures from separate pieces — typically brick, stone, or concrete — bound by mortar. The resulting surface is strong, fire-resistant, and visually appealing. It’s used in walls, foundations, chimneys, fireplaces, and facades, forming both load-bearing and decorative elements of a building.

Because of its versatility, masonry fits into a wide range of projects, from single-family homes and retaining walls to large commercial facilities.

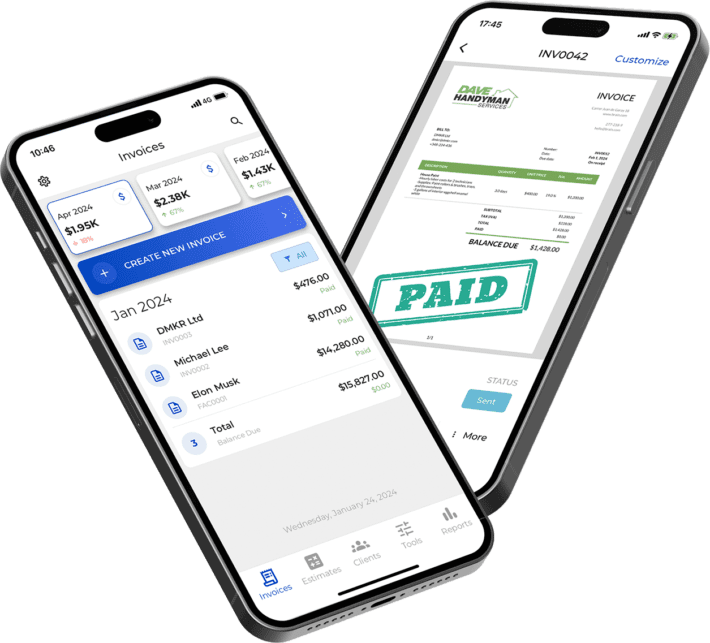

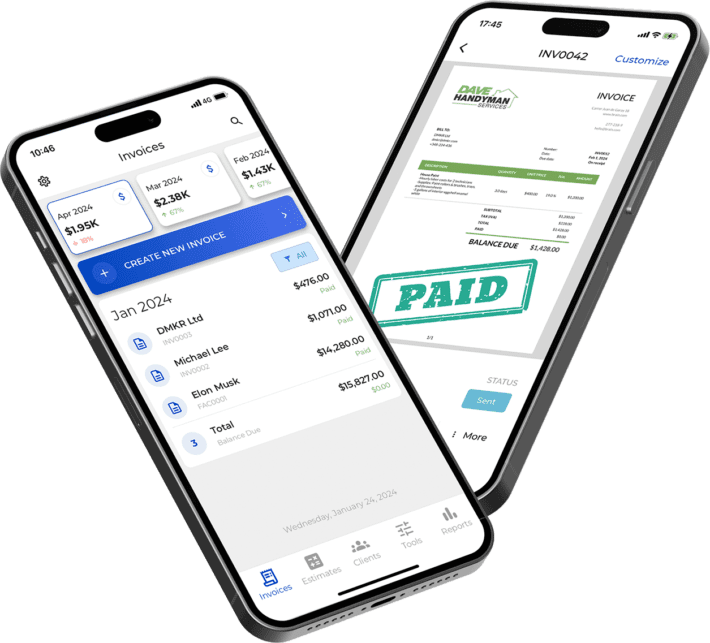

Get Started with Invoice Fly’s Software

Invoice Fly is a smart, fast, and easy-to-use invoicing software designed for freelancers, contractors, and small business owners. Create and send invoices, track payments, and manage your business — all in one place.

History and Importance of Masonry

Humans have relied on masonry for thousands of years. For example, think of the Great Wall of China or the Roman Colosseum. These structures stand as proof of masonry’s resilience.

Today

Modern construction has evolved, but the principles of masonry remain the same. Today’s masons use advanced tools, pre-mixed mortar, reinforced systems, and lightweight blocks, combining ancient craftsmanship with modern efficiency.

Masonry continues to be popular for its energy efficiency, fire resistance, and low maintenance, as well as its ability to enhance property value and curb appeal.

Types of Masonry in Construction

Masonry isn’t one-size-fits-all. The type you choose depends on materials, structural needs, and design goals.

Brick Masonry

The most common type, known for its neat appearance and reliability. It involves laying rectangular clay bricks in a pattern and bonding them with mortar.

- Advantages: Durable, cost-effective, and fire-resistant.

- Applications: Walls, fireplaces, and facades.

- Example: A solid brick house or brick veneer wall that provides strength and insulation.

Stone Masonry

This type uses natural stones like granite, limestone, or marble. It’s one of the oldest methods, valued for its beauty and longevity.

- Advantages: Extremely durable, weather-resistant, and aesthetic.

- Disadvantages: Labour-intensive and more expensive.

- Applications: Decorative walls, monuments, and foundations.

Concrete Masonry Units (CMUs)

These are precast concrete blocks that form structural and non-structural walls.

- Advantages: Cost-efficient, fast to install, excellent load-bearing strength.

- Types: Standard blocks, hollow blocks, and architectural CMUs.

- Applications: Commercial buildings, basements, and retaining walls.

To learn how to price your concrete work effectively, check out How to Price Concrete Jobs.

Veneer Masonry

Veneer uses a single layer of decorative material (brick or stone) attached to a backing wall. It’s non-structural but gives the appearance of solid masonry.

- Advantages: Lightweight, cost-effective, easy to maintain.

- Applications: Residential exteriors, fireplaces, and interior accent walls.

This system combines visual appeal with reduced material costs and labour time.

Reinforced and Unreinforced

- Reinforced: Uses steel bars or mesh embedded in mortar or concrete to increase tensile strength and resist seismic loads. Common in multi-storey and commercial structures.

- Unreinforced: Relies solely on mortar and material strength, ideal for small buildings and walls where high loads aren’t expected.

Masonry Materials and Tools

Mortar and Its Role

Mortar acts as the glue that binds masonry units together. It’s typically made from cement, lime, sand, and water, providing both adhesion and flexibility.

Different mortar types (M, S, N, O) are used based on load and exposure conditions. For example, Type M for foundations and Type N for general walls.

Common Materials

- Brick: Clay-based and kiln-fired for strength.

- Stone: Natural and durable, often used in high-end projects.

- Block: CMUs or lightweight concrete blocks for structural walls.

- Cement: The key binder in mortar and concrete masonry.

Explore the tools and equipment you’ll need in our Construction Tools Guide.

Tools Used in Masonry Work

Masons rely on specific tools, including:

- Trowel: For spreading mortar.

- Spirit level: For ensuring alignment.

- Brick hammer and chisel: For cutting and shaping units.

- Joint raker: For finishing mortar joints.

- Mortar board and bucket trowel: For consistent mixing and application.

Common Techniques

Pointing and Joint Finishing

Pointing in masonry means filling or repairing mortar joints to improve waterproofing and appearance. Clean, well-finished joints prevent moisture penetration and extend wall life.

Bond Patterns in Brickwork

Bonds refer to the arrangement of bricks to ensure stability. Popular patterns include:

- Stretcher Bond (standard running bond)

- English Bond (alternating headers and stretchers)

- Flemish Bond (decorative and structural)

Each pattern impacts wall strength, load distribution, and aesthetics.

Load-Bearing vs. Non-Load-Bearing

- Load-bearing walls support the weight of the structure above.

- Non-load-bearing walls serve mainly as partitions or decorative facades.

Understanding this distinction helps contractors select the right materials and reinforcement.

Advantages and Disadvantages of Masonry Construction

Strength, Durability, and Fire Resistance

Masonry is valued for its compressive strength and longevity. It resists fire, pests, and weathering better than most construction materials. These walls also provide thermal mass, improving energy efficiency.

Cost, Labor, and Maintenance

The main downsides are labour cost, installation time, and weight. These jobs require skilled masons, and improper workmanship can lead to cracks or moisture issues.

However, maintenance is minimal once construction is done, a key reason it remains popular in both residential and commercial projects.

Simplify your project planning with Invoice Fly’s Estimates App and create accurate cost estimates for jobs in minutes.

Applications in Modern Construction

Residential and Commercial Uses

Masonry appears in nearly every sector:

- Residential: Homes, patios, driveways, fireplaces, and retaining walls.

- Commercial: Office buildings, schools, and warehouses built with CMUs or reinforced systems.

- Industrial: Factories and storage units requiring high fire and load resistance.

Explore the latest construction industry trends to see how masonry is being modernized with prefab and sustainable materials.

Restoration and Conservation Projects

Masonry restoration involves cleaning, repointing, and repairing old structures without losing their character. Historic buildings often require specialized materials and techniques to preserve their integrity.

Real-life Example: Centre Block of Parliament Hill, Canada

A notable large-scale example is the Centre Block of Parliament Hill in Canada, one of the country’s most significant restoration projects. The work includes the removal and replacement of more than 365,000 stones, progressing from the north wall to the east, west, and south facades.

Each stage requires careful cleaning, joint raking, and repair of underlying steel components before the walls are rebuilt around them. This decades-long effort showcases how restoration blends traditional craftsmanship with modern engineering precision.

A Craftsmanship For The Ages

Masonry remains one of the foundations of modern construction blending traditional craftsmanship with today’s engineering standards. Whether it’s brick, stone, or concrete, each type offers unique benefits in terms of strength, cost, and design flexibility.

For contractors and builders, mastering masonry means delivering projects that last for generations when paired with the right tools, materials, and cost tracking.Send professional invoices and track expenses easily with Invoice Maker, free to use and built for small construction businesses who prioritize efficiency.

Get Started with Invoice Fly’s Software

Invoice Fly is a smart, fast, and easy-to-use invoicing software designed for freelancers, contractors, and small business owners. Create and send invoices, track payments, and manage your business — all in one place.

FAQs About Masonry

Brick, stone, and concrete are the most common, though veneer and reinforced systems are also widely used.

Not entirely. Masonry is porous, so sealing and proper pointing help prevent water infiltration.

Yes, applying a breathable sealer protects walls from moisture damage and staining.

Use masonry paint designed for concrete, brick, or stone surfaces. It allows the wall to breathe while resisting weathering.

Small repairs or decorative veneer projects can be DIY-friendly. Structural or load-bearing masonry should always be handled by a professional.

A large, solid heating system built from brick, stone, or concrete that stores heat from a short, hot fire and releases it slowly over many hours. Unlike metal stoves, it radiates gentle, consistent warmth long after the fire burns out, making it an efficient and eco-friendly heating solution.